The ongoing trend of miniaturisation within the connector market is a direct response to consumer demands for more compact electronic and industrial equipment. Devices such as sensors, cameras and automation equipment are rapidly decreasing in size, while displays and screens are becoming increasingly thinner and flatter. However, as these components get smaller, they simultaneously need to increase in power to meet the expanding data, signal and power requirements of consumers.

As a result, it stands to reason that device connectors themselves must also decrease in size to ensure they do not take up too much of the limited installation space available on new, miniaturised equipment. Device manufacturers are therefore redesigning products in ever shorter cycles to ensure they are both future-proof and tough enough to cope with demanding environments.

As a result, it stands to reason that device connectors themselves must also decrease in size to ensure they do not take up too much of the limited installation space available on new, miniaturised equipment. Device manufacturers are therefore redesigning products in ever shorter cycles to ensure they are both future-proof and tough enough to cope with demanding environments.

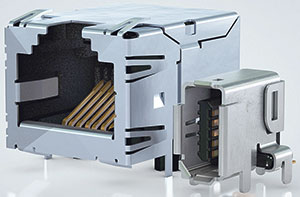

As part of this move towards miniaturisation, HARTING has recently released the ix Industrial, a robust Ethernet interface to provide the next generation of compact products with perfect high data transmission rates. The ix is designed to replace the traditional RJ45, as it is too large to use in the latest micro products.

In order to resolve the sizing issue, HARTING has made the ix Industrial PCB jack 70% smaller than the RJ45 socket. Not only does it mean the ix can be easily incorporated into smaller devices, it also allows a significantly higher packing density as the spacing between the sockets is just 10 millimetres.

In addition, the ix combines both data transmission and power supply into a single interface, further reducing the area taken up by connectors. This can prove extremely useful within the public transportation market, as flat screen displays and passenger information systems can be supplied with both power and data via the ix interface. Despite its reduced size, the ix Industrial still produces Cat. 6A performance for 1/10Gbit/s Ethernet at a control level.

HARTING’s PushPull connector technology has also been specifically designed to meet the demands of new, high-tech manufacturing environments. As businesses embrace more flexible production processes, the ability to quickly and efficiently disconnect and reconnect the industrial lifelines of data, signal and power is vital if expensive machine downtime is to be avoided.

PushPull incorporates an uncomplicated connection and termination technique that ensures absolute dependency and reliability. This intuitive, tool-free method guarantees an error-free, secure connection as the two sections are clicked into place, allowing interfaces to be changed quickly and easily without the need for specialist training.

Users can even allocate colour codes to each PushPull plug and socket in an installation to help reduce cabling errors. For example, you can easily colour code data, signal and power lines to ensure each one is distinct and easily identifiable.

Users can even allocate colour codes to each PushPull plug and socket in an installation to help reduce cabling errors. For example, you can easily colour code data, signal and power lines to ensure each one is distinct and easily identifiable.

While it is vital to ensure performance levels and innovative new designs are able to meet consumer requirements, reliability of new products is equally important. HARTING place great emphasis on the precision and quality of their designs to ensure they are robust and durable enough for a wide range of applications.

By undertaking rigorous testing of IPx protection, mating reliability, robustness, vibration resistance and EMC safety, you can rest assured that all critical factors have been assessed and production completed to the highest standards. As a result, users are able to rely on powerful and proven systems that are designed precisely for their applications.

With their PushPull V4 Industrial range, HARTING created a connector with a resilient, one-piece housing material which protects the connection from aggressive chemicals such as cutting oils.

This means it can be utilised in both harsh industrial environments and outdoor applications. The V4 Industrial also comes with additional IP65/67 protection covers on both ends, meaning you are safeguarded from total dust ingress and water.

Similarly, the ix Industrial has also been designed and built to withstand the rigours of industrial environments, resolving the issues associated with the RJ45, whose plastic locking tabs are easily broken. The socket and connector are securely locked together by two metal snap-in hooks, ensuring a robust and vibration-proof connection from the cable to the circuit board for up to 5,000 mating cycles.

Industry standards are also an important facet of new connector technology. They ensure the reliability and compatibility of new products while speeding up the time it takes to get a new development to market.

Both the ix Industrial and PushPullV4 Industrial have been thoroughly tested to ensure they meet the required standards. The housing of the V4 has been tested according to Railway Standards for shock, vibration and temperature, meeting EN 45545-2, while the ix complies with IEC 61076-3-124 and conforms to the shock and vibration resistance levels set out in EN 50155 railway specifications. As a result, consumers have security in terms of planning and peace of mind that these products can stand up to the toughest of tests.