In this issue of Industry Update, we are delighted to select RM Fowler Limited as our Linear Motion Specialist Company of the Month.

Linear motion components are a vital part of precision machines used in a wide range of industries around the world. R M Fowler Limited has chosen to specialise in linear guides and ball screws from one of the world’s leading manufacturers of linear technology: NSK.

Linear motion components are a vital part of precision machines used in a wide range of industries around the world. R M Fowler Limited has chosen to specialise in linear guides and ball screws from one of the world’s leading manufacturers of linear technology: NSK.

RM Fowler stock a large quantity of NSK linear products in their UK warehouse, and with advanced-precision cutting facilities on site they can cut linear guides and ball screws to desired lengths quickly and efficiently. R M Fowler are also proud to be the sole UK distributor for the American based Inverted tooth chain company: Ramsey Products Corporation and are also an authorised distributor for Nippon Bearings (NB).

R M Fowler was established in 1998 and became an official NSK distributor in 2000. Their in-house team support Original Equipment Manufacturers (OEM) and machine builders providing engineering knowledge and expertise. The specialist customer service team understand how linear motion components and ball screws form a vital part of precision machines. They provide technical advice over the phone and understand the importance of advancements in technology, product application and obsolescence management. The team continuously communicate directly with NSK’s distribution and supply teams to ensure consistent product availability.

NSK has continued to develop and supply motion solutions through their range of bearings, precision machine components and automotive products. Only the best quality raw materials from ethical sources are used to make NSK products and with their advanced production techniques and precision grinding NSK Linear products are built to a high specification as standard, as a result NSK linear off- the-shelf products are suitable for most applications without the need to have a higher specification manufactured on long lead times.

NSK has continued to develop and supply motion solutions through their range of bearings, precision machine components and automotive products. Only the best quality raw materials from ethical sources are used to make NSK products and with their advanced production techniques and precision grinding NSK Linear products are built to a high specification as standard, as a result NSK linear off- the-shelf products are suitable for most applications without the need to have a higher specification manufactured on long lead times.

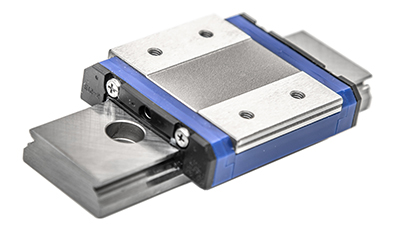

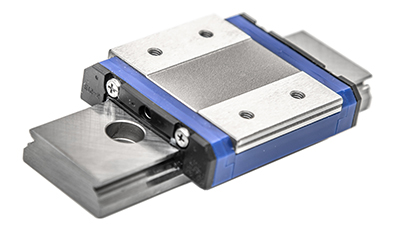

NSK Linear guides from the NH and NS series are manufactured in the UK, through NSK’s state of the art tribological and analytical technologies a new ball groove geometry has been developed offering maximum precision combined with extremely high load ratings and long service life. Outstanding accuracy means that the object in motion is positioned precisely and moves optimally. It also guarantees smooth, even running.

The NH series can be customised in a number of ways for special en vironments, this includes high temperature versions with no plastic parts, extra sealing for improved dust protection or utilising the NSK K1-L™ unit. Stainless steel and surface treatments are also available.

vironments, this includes high temperature versions with no plastic parts, extra sealing for improved dust protection or utilising the NSK K1-L™ unit. Stainless steel and surface treatments are also available.

Installing the optional NSK K1-L™ lubrication unit on linear guides ensures effective lubrication extending maintenance intervals and reducing cost. The NSK K1-L™ lubrication device is made from a porous synthetic resin containing a large amount of lubrication oil. As the linear guide operates, the NSK K1-L™ provides fresh oil to the contacting surfaces.

For further information on any of NSK’s linear range, please contact the Customer Service Team:

T 01565 651051

sales@rmfowler.co.uk

www.rmfowler.co.uk