In the realm of metal fabrication, Charles Day Steels understand that precision and efficiency are paramount. Over the years, various cutting methods have emerged, each with its own advantages and limitations, and as leading providers of metal profiling solutions, we endeavour to develop a series of metal profiling services to meet a range of requirements. One such method that has gained significant popularity is waterjet cutting.

Perfect for a diverse range of applications, profiling via a waterjet machine hosts a range of versatile benefits, some of which include:

Perfect for a diverse range of applications, profiling via a waterjet machine hosts a range of versatile benefits, some of which include:

Versatility in material compatibility

One of the standout features of waterjet cutting is its compatibility with a wide range of metal materials. Whether it’s aluminium, stainless steel, titanium, copper, brass, or alloys, waterjet cutting can precisely profile these metals without causing any heat-induced distortion or altering their inherent properties. This characteristic is particularly crucial for industries that require intricate cuts and shapes while maintaining the material’s integrity.

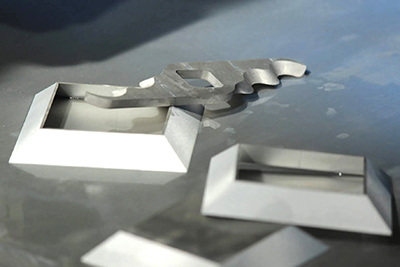

Intricate and complex designs

Waterjet cutting technology allows for precise and intricate metal profiling, making it ideal for industries that demand complex designs and tight tolerances. The high-velocity water stream can effortlessly manoeuvre through metal, creating intricate patterns, holes, and sharp corners that may be challenging to achieve using alternative cutting methods. This versatility enables manufacturers to produce intricate components and parts for industries such as aerospace, automotive, architecture, and more.

No Heat-Affected Zone (HAZ)

Unlike traditional heat-based cutting methods like plasma cutting or laser cutting, waterjet cutting operates without generating heat during the cutting process. The absence of heat eliminates the risk of thermal distortion, melting, or hardening of the metal. Consequently, waterjet cutting minimises the formation of a heat-affected zone (HAZ), ensuring that the cut edges retain their original properties, such as strength, hardness, and structural integrity. This characteristic is particularly vital for applications where material properties cannot be compromised.

Environmentally friendly and safe

Environmentally friendly and safe

Waterjet cutting stands out not only for its versatility but also for its eco-friendly nature. The cutting process is typically water-based, and the water used can be recycled and reused, reducing water consumption significantly. Additionally, waterjet cutting does not involve the use of hazardous chemicals or produce harmful fumes, making it a safe and clean cutting method for operators and the environment alike.

Minimal secondary processing

Another advantage of waterjet cutting in metal profiling is the reduced need for secondary processing. The precise and clean cuts achieved by waterjet technology often eliminate the necessity for additional finishing, such as grinding and deburring. This saves time, labour costs, and ensures a more efficient production process; providing an economically viable alternative.

Charles Day and the Waterjet Sweden BevelJet 60

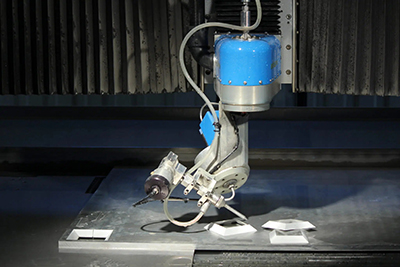

Charles Day is proud to possess three of the UK’s largest cutting beds for waterjet cutting services, and can profile materials up to 9m x 4m in size. Drawing on relevant technologies as part of our continuous ethos for self-improvement, we have also invested in our latest revolutionary waterjet machine, the Waterjet Sweden BevelJet 60.

Renowned as one of the most advanced pieces of metal profiling technology available on the market, this newest addition to our unrivalled suite of profiling machines allows our professionals at Charles Day to meet the most stringent of material specifications. Featuring dual cutting heads (3D and 2D), 125hp pump, and adjustable pressures for rapid cutting, the Waterjet Sweden BevelJet 60 is yet another invaluable improvement in Charles Day’s legacy.

Read more about our latest Machine Investment

T 0114 244 5544

sales@daysteel.co.uk

www.daysteel.co.uk