In this issue of Industry Update, we are pleased to feature HEIDENHAIN (G.B.) Limited as our Measurement, Control, and Drive System Technology Company of the Month.

HEIDENHAIN is a high-tech company that has been pioneering in measurement, control, and drive system technology for more than 130 years. HEIDENHAIN products often lay the groundwork for technological advances in the most innovative global industries, including semiconductors, electronics, machine tools, and production equipment automation for the factories of tomorrow.

HEIDENHAIN is a high-tech company that has been pioneering in measurement, control, and drive system technology for more than 130 years. HEIDENHAIN products often lay the groundwork for technological advances in the most innovative global industries, including semiconductors, electronics, machine tools, and production equipment automation for the factories of tomorrow.

Founded in Berlin in 1889, this pioneering company for measurement and control technology looks back on a long tradition. HEIDENHAIN, located in Traunreut in southern Bavaria, now offers products and solutions for industries such as machine tools, automation, electronics, robotics, elevators, and medical technology.

HEIDENHAIN has an established network of 30 subsidiaries and 40 distributors worldwide. HEIDENHAIN (G.B.) Limited, a wholly owned subsidiary of DR. JOHANNES HEIDENHAIN GmbH was founded in 1969 and is based in Burgess Hill, West Sussex, and is responsible for the UK and Ireland territories.

HEIDENHAIN has an established network of 30 subsidiaries and 40 distributors worldwide. HEIDENHAIN (G.B.) Limited, a wholly owned subsidiary of DR. JOHANNES HEIDENHAIN GmbH was founded in 1969 and is based in Burgess Hill, West Sussex, and is responsible for the UK and Ireland territories.

Research and development are part of HEIDENHAIN’s DNA, with a double-digit percentage of its revenues devoted to the continual development of its advanced technologies. Its market leading technologies incorporate reliability, repeatability, and accuracy at its core.

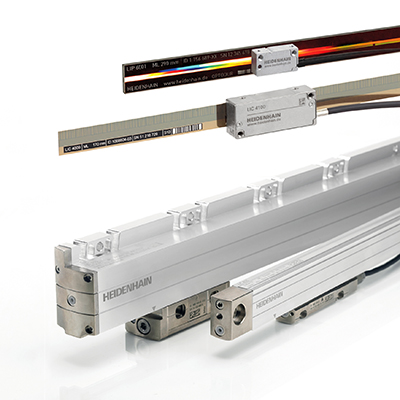

Daniel Johnson, MD HEIDENHAIN GB commented on some recently launched products for the UK market, “For 2024, HEIDENHAIN is launching our new control ‘the TNC7’ into the UK machine tool market, along with our new generation of feedback encoders with built in vibration sensors for predictive maintenance. Our new control addresses many modern machining shop problems faced by our users such as the total cost of ownership over the machine lifespan. The TNC7 control has been developed to reduce setup times through graphically assisted probing of the work piece and fixtures. We have advanced the technology of linear scales by reducing and/or eliminating the need for air purge without compromising on signal quality and reliability. Improvements in the machines cutting performance through optimised contour milling, reducing tool wear and milling times. Enhanced dynamic collision monitoring and in process monitoring without additional sensors vastly reduces the chances of downtime due to collisions or tool breakages.”

“Furthermore, our latest generation of rotary feedback encoders have additional sensors built in such as temperature or vibration, utilising our EnDat protocol to transmit the data allowing production lines to manage alerts before they become production stoppages.”

“Furthermore, our latest generation of rotary feedback encoders have additional sensors built in such as temperature or vibration, utilising our EnDat protocol to transmit the data allowing production lines to manage alerts before they become production stoppages.”

In support of these new products, HEIDENHAIN is increasing its support for customers in the UK by bringing on board service and training partners in the UK and Ireland, as well as adding additional facilities in Burgess Hill that will also include a full 5 axis milling machine to enhance customer training and application support.

In rapidly changing technological landscapes, adaptability is key. HEIDENHAIN GB is poised to adapt to the latest UK market trends, regulatory changes and technological advancements swiftly, ensuring to remain competitive in its industry. Understanding and addressing customer needs is crucial for success. “We measure success by seeing our customers succeed, breading long lasting relationships built on trust and industrial products,” added Daniel.

For more information, please see below:

T 01444 238550

sales@heidenhain.co.uk

https://www.heidenhain.co.uk