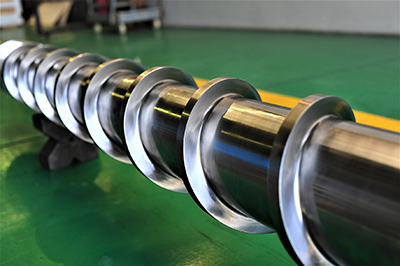

Hertfordshire based engineering company, Magog Industries continue to develop it’s range of bimetallic alloy hardened grades and coatings, working closely with established UK and European based coating specialists. Plastics recycling is growing within the industry with many moulders increasingly recycling in-house.

However, where recycled material needs to be bought in, problems can arise where material contain abrasive elements that pose a challenge in processing. For example, added fibres used to reinforce the moulded product can now be as high as 50%. Certain PE and some grades of bio-degradable polymers such as PVOH (Polyvinyl Alcohol) can attack the screw surface over time.

However, where recycled material needs to be bought in, problems can arise where material contain abrasive elements that pose a challenge in processing. For example, added fibres used to reinforce the moulded product can now be as high as 50%. Certain PE and some grades of bio-degradable polymers such as PVOH (Polyvinyl Alcohol) can attack the screw surface over time.

At Magog Industries, Director and General Manager, John Allsop is leading the drive in developing and presenting solutions, “We’ve been focussing on looking at measures, particularly surface treatment for abrasion and potential corrosion to increase resilience and longevity specifically in ceramic and chrome seal coatings for demanding applications such as blown film extrusion.” John explained, “By working closely with our customers, we continue to innovate and develop our products to ensure latest solutions are available to meet the most demanding process applications.”

“For example, the recycling and re-processing market has grown in recent years for both new and refurbished screws and barrels for the company. Regrind material can bring its own challenges but are successfully met thanks to many years of expertise within our design, engineering and production teams.”

For more information, please contact Magog Industries by email: enquiries@magog.co.uk, call: 01920 465201 or visit: www.magog.co.uk