Engilico’s SealScope™ helps to minimise customer complaints on badly sealed packages, reducing waste from tons per year to just a few packages per month.

Industry Update is proud to announce that Engilico has been selected as our Packaging Technology Company of the Month, for the development of its outstanding systems to inspect and monitor sealing processes.

Founded in 2011 by Olivier Georis and Peter Nijs, Engilico’s headquarters is based in Leuven, with sales offices in Germany and the US and a worldwide distributor and partner network. With a vast range of clients for whom the preservation of package content is critical, Engilico boasts over 150 installations at top international companies, including Unilever, General Mills, FrieslandCampina, Materne, Ecolab, Puratos and many more.

Founded in 2011 by Olivier Georis and Peter Nijs, Engilico’s headquarters is based in Leuven, with sales offices in Germany and the US and a worldwide distributor and partner network. With a vast range of clients for whom the preservation of package content is critical, Engilico boasts over 150 installations at top international companies, including Unilever, General Mills, FrieslandCampina, Materne, Ecolab, Puratos and many more.

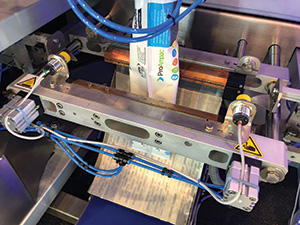

Engilico’s key solution is SealScope™ for 100% seal inspection of flexible packages. During the closing of a package, the sealing status is measured using sensors that are retrofitted to the sealing bars of the packaging machine. Every seal measurement is then compared to the reference signal of a good seal, helping to identify and reject packages that have been compromised due to wrinkles, folds or product in the sealing area. “By 100% inspecting the sealing process, the number of incidental wrong packages can be reduced by a factor of 10 or more,” said Renaat Van Cauter, Marketing Director. “Also, using the monitoring function of SealScope™, the production line can be optimised to increase packaging speed while preserving the sealing quality.”

Indeed, because SealScope™ is integrated directly into the packaging machine, Engilico can provide 100% in-line sealing inspection and process monitoring. This leads to a number of advantages for clients, including better packaging quality, increased packaging productivity and elimination of manual inspection enabling end-of-line automation.

One of Engilico’s customers, SCHOEPS, chose SealScope™ to inspect its grated cheese bags for defective seals, which is a prevalent issue as the product is packaged under modified atmosphere conditions. Yannick Baudoux, owner of SCHOEPS, commented, “We drastically reduced our customer complaints on badly sealed packages. Before the installation of SealScope™, about 1% of the 3,500 ton outgoing production was returned with micro-leaks. This has now dropped to a few packages.” Indeed, such an enviable feat is proof of the unrivalled capabilities of Engilico’s seal inspection solutions.

One of Engilico’s customers, SCHOEPS, chose SealScope™ to inspect its grated cheese bags for defective seals, which is a prevalent issue as the product is packaged under modified atmosphere conditions. Yannick Baudoux, owner of SCHOEPS, commented, “We drastically reduced our customer complaints on badly sealed packages. Before the installation of SealScope™, about 1% of the 3,500 ton outgoing production was returned with micro-leaks. This has now dropped to a few packages.” Indeed, such an enviable feat is proof of the unrivalled capabilities of Engilico’s seal inspection solutions.

With a dedication to continuous innovation, Engilico is also focusing on solutions to help detect contamination in seals of thermoformed packages and trays. HyperScope™ uses hyperspectral imaging (HSI) technology for the detection of contamination in the seal with a much higher contrast than traditional vison-based systems. “One of its main benefits is that it measures through both transparent and printed films,” Renaat elaborated, “the latter of which is impossible for standard vision cameras.”

As well as these recent product developments, Engilico has been expanding its sales and marketing activities in both Europe and the US. “As demand has been growing strongly in the US, we recently established a subsidiary in the US to allow our customers to work directly with local Engilico sales and support staff. Also, our goal is to significantly increase the awareness of Engilico’s capabilities of sealing inspection in the packaging industry by attending worldwide tradeshows, publicising customer stories, and developing online media.”

Of course, Engilico’s expert capabilities are continuously evolving. As packaging continues to progress, inspection technologies must also be refined to keep up with new packaging types, productivity, and quality levels, a challenge which Engilico is more than capable of addressing.

For more information, please see the contact details below.

T +32 16 498 130

info@engilico.com

www.engilico.com/seal-inspection