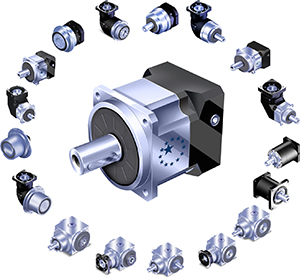

During these unprecedented times, manufacturers in the UK not only need automated processes to boost productivity and speed to market so that they can remain competitive, but they also require production machinery that is ultra-reliable and can operate at the required capacity, says APEX Dynamics, a leading supplier of high-precision gearboxes.

The coronavirus pandemic has led to a different way of working for manufacturers, with enforced social distancing measures implemented in the workplace area to create safe spacing impacting on operations, exacerbated by staff that have been furloughed or affected by the virus taking time off.

The coronavirus pandemic has led to a different way of working for manufacturers, with enforced social distancing measures implemented in the workplace area to create safe spacing impacting on operations, exacerbated by staff that have been furloughed or affected by the virus taking time off.

That is why it’s even more vital for machinery to avoid any unnecessary downtime.

Manufacturers need to decide when working with a supplier what their capabilities are and how they are structured for the ‘new normal’. APEX Dynamics’ UK Sales Manager, Andrew Parsons, doesn’t think requirements have changed from reliable delivery, quality product, competitive costing and great service, but the current situation may have repercussions for how suppliers can now perform.

He said, “Automation is a key area for being able to handle social distancing and production capacity – highly automated processes they require less close operator interaction. In turn a reliable motion control system is critical for keeping production lines operating to maximum effect by reducing the amount of time lost for manual intervention.

He said, “Automation is a key area for being able to handle social distancing and production capacity – highly automated processes they require less close operator interaction. In turn a reliable motion control system is critical for keeping production lines operating to maximum effect by reducing the amount of time lost for manual intervention.

“Reliable deliveries and service are more important than ever, so a supplier must look at what the lead times are and how that fits in with their build times. APEX Dynamics has remained unchanged in the crisis, still offering three-week deliveries on all standard products and the only five-year warranty in the industry, with video conferencing available to discuss applications.”

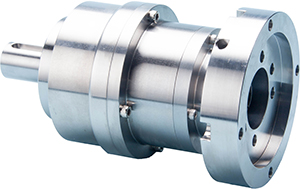

As well as the advanced manufacturing facility, which includes the full product heat treatment process and gear cutting, APEX Dynamics has patents for its gearboxes that offer unique advantages, such as the bearing mounted sun gear, planet carrier design, input and output sealing with hi-tech ball burnished surfaces and Teflon-coated Viton seals allowing high efficiency and low heat.

Andrew commented, “The optimum design, material and construction of our gearboxes cannot be copied. Although imitations may look very similar from the outside, they won’t have the same performance, quality and warranty that APEX offers and can lead to early failure, more downtime and a risk of reputation damage.

“Optimum design, lubrication and sizing is key to ensuring the lifetime of gearboxes is as long as possible. Special cut channels on the planet gears allow lubrication to flow to the needle bearings during rotation increasing circulation through the bearing, reducing heat build-up and increasing life.”

“Optimum design, lubrication and sizing is key to ensuring the lifetime of gearboxes is as long as possible. Special cut channels on the planet gears allow lubrication to flow to the needle bearings during rotation increasing circulation through the bearing, reducing heat build-up and increasing life.”

Reducing backlash to a perfect zero has been the holy grail for precision gearbox manufacturers and, whilst some companies may claim this level of perfection, it is in actual fact an impossible goal. However, it is possible to supply precision-built gearboxes that can keep operating to maximum effect by ensuring extremely close-tolerance alignment of components in a motion control system.

Reducing backlash to a perfect zero has been the holy grail for precision gearbox manufacturers and, whilst some companies may claim this level of perfection, it is in actual fact an impossible goal. However, it is possible to supply precision-built gearboxes that can keep operating to maximum effect by ensuring extremely close-tolerance alignment of components in a motion control system.

Building an ultra-precise gearbox to obtain near-zero backlash requires taking measures to avoid workmanship defects such as incorrect tolerances, bearing misalignment and manufacturing inconsistencies which all tend to increase the risk of more backlash. To achieve as close to perfection as possible it’s necessary for gearbox manufacturers to invest heavily in specialised tooling and procedures in order to yield the end result of higher accuracy.

Today’s current climate presents huge challenges for manufacturers and suppliers alike. Highly reliable automated processes require less close operator interaction, which will be key to manufacturing at the required capacity during and after social distancing.

Find out more at: www.apexdynauk.com