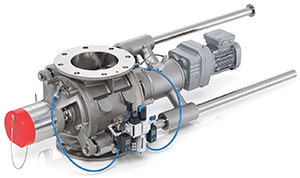

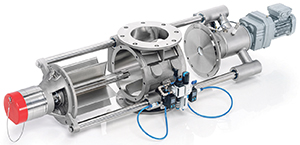

DMN-WESTINGHOUSE introduces a new rotary valve for the food processing dry bulk industry that is intended for dosing products and ingredients.

With the new MZC-II rotary valve, the producer of rotary valves and diverter valves is setting a new standard in terms of functionality, hygiene, safety and maintenance. DMN-WESTINGHOUSE introduced the current MZC rotary valve 25 years ago, which has played an important role in increasing food safety in production processes of companies in the food and dairy segment, among others. With the introduction of this new rotary valve, which can be opened on two sides and thus creates optimal conditions for hygiene, safety, functionality and maintenance, DMN-WESTINGHOUSE continues a tradition of products that are characterised by high-quality engineering, durability and continuity.

With the new MZC-II rotary valve, the producer of rotary valves and diverter valves is setting a new standard in terms of functionality, hygiene, safety and maintenance. DMN-WESTINGHOUSE introduced the current MZC rotary valve 25 years ago, which has played an important role in increasing food safety in production processes of companies in the food and dairy segment, among others. With the introduction of this new rotary valve, which can be opened on two sides and thus creates optimal conditions for hygiene, safety, functionality and maintenance, DMN-WESTINGHOUSE continues a tradition of products that are characterised by high-quality engineering, durability and continuity.

Due to increasingly strict requirements in the field of hygiene and efficiency, DMN-WESTINGHOUSE has decided to significantly improve the MZC rotary valve. That is why, at the beginning of 2020, a start was made on developing the new standard and further developing the current rotary valve with the aim of achieving a version that is capable of being the benchmark for the long-term, in particular for the food processing sector. DMN-WESTINGHOUSE gave the first product demo of the MZC-II rotary valve during the DMN-WESTINGHOUSE Global Salesforce Event in May of this year.

Risks of downtime significantly reduced

Risks of downtime significantly reduced

The MZC-II is highly distinctive when it comes to aspects such as safety and hygiene, and ensures a significant reduction in downtime risks. Due to its double-sided opening, the new rotary valve is so intuitive to use, every professional on the workplace can use, open, clean and maintain it without detailed knowledge. No specific instruction or knowledge is required to operate the rotary valve, and optimal access to the drive end also allows extra thorough user-friendly cleaning.

Wim Korndorffer, CEO of DMN-WESTINGHOUSE, said, “The MZC-II rotary valve not only contributes to improving hygiene conditions, but also improves efficiency. This significantly reduces the risk of downtime due to damage and adjustment problems. Because we have taken significant steps in the field of hygiene, safety and efficiency during the periodic cleaning and maintenance activities, we can make an important contribution to the further improvement of productivity, safety and quality for our customers in the dry bulk industry, from pharmaceuticals to dairy and from paint to cosmetics. Long-term tests under various conditions in a professional and critical production environment, including a pilot with an important customer, have proven this. Therefore, we are very excited that we can now launch this product.”

T +44 (0)1249 818400

dmn.uk@dmnwestinghouse.com

www.dmnwestinghouse.com