In this issue of Industry Update, we are delighted to select BW Flexible Systems as our Packaging Systems Company of the Year.

BW Flexible Systems is part of Barry-Wehmiller businesses, under BW Packaging and works alongside four other companies: Synerlink, Pneumatic Scale Angelus, BW Integrated Systems, and Accraply to collaboratively supply global high-quality packaging solutions, across 40 locations. BW Flexible Systems manufacturers flexible packaging solutions including: bag filling and palletising, vertical form-fill-seal, and horizontal flow wrapping, for food: bakery, frozen foods to fresh produce and non-food products: pharmaceutical, agriculture to pet food industries.

The expert wide range of machinery options include:

The expert wide range of machinery options include:

- Form-fill sealing

- Feeding, bag filling and sealing

- Pouch-making equipment

- Flow wrap

- Re-closable packaging solutions

- Stretch-wrapping

- Paper & mailer insertion

- Collating

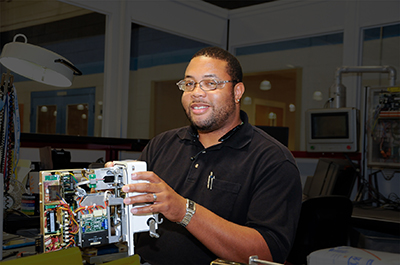

BW Flexible Systems has over 100 years’ expertise across the industry and is well versed in supporting businesses with bespoke solutions, through its unparalleled, strategic customer support. Using the streamlined power of brands such as Hayssen, Rose Forgrove to Sandiacre, this market-leading packaging solutions powerhouse offers world-class bespoke support. This cutting-edge manufacturer is renowned for its people-centric ethos, from staff to customers, everyone is valued.

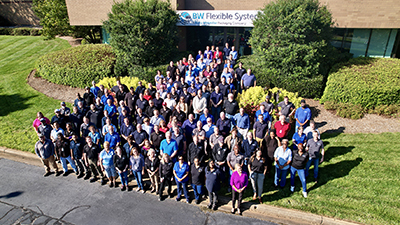

We spoke to James Beresford-Wylie: FFS EMEA Sales Director to find out more about how the company has fared over the last twelve months, “The company has had a highly successful 2022/2023 season. Our teams have released several new products and are working on a few more in the pipeline, some of which are expected to be released at the start of Spring next year.”

“Our teams have grown tremendously over the past year and through this growth, many of our internal processes and structures, as well as products, have become more streamlined and efficient, to ensure our customers get the best support possible and the ideal solutions for

“Our teams have grown tremendously over the past year and through this growth, many of our internal processes and structures, as well as products, have become more streamlined and efficient, to ensure our customers get the best support possible and the ideal solutions for

their applications.”

“It is a perfect marriage between the iconic brands: Rose Forgrove and Sandiacre, which serve as a solid and stable foundation, with new perspectives and skills offered by the larger corporation of Barry-Wehmiller that help BW Flexible Systems make huge strides in development and innovation.”

With a focus on consolidated efforts, streamlining processes and optimised customer focus, the company has undergone some recent organisational changes. By combining teams, maximising alignment and other considered strategic decisions, BW Flexible Systems has ensured that all divisions are running smoothly, with customers at the heart of all operations.

Working across food and non-food products, means that the team can support many diverse industry applications, with first-class sustainable, hygienic and practical packaging solutions. We asked James what gave the products an edge over competitors, “We have a huge product portfolio, global footprint with local support, embedded in local languages, great customer service, and a genuine interest in building effective relationships. We always value making the right decision for the customer, above all else.”

Furthermore, the Truly Human Leadership strategy underpins all employee operations and is designed to bolster the wellbeing of all staff. The philosophy centres on staff-centric approaches, ensuring they have bespoke support, respect and dignity, allowing them to have a happy and fulfilling work/life balance. With Bob Chapman: CEO of Barry-Wehmiller at the helm, this strategy helps company leaders across the board engage with their teams with empathy and compassion, leading to higher work morale and therefore, optimising customer service levels.”

Furthermore, the Truly Human Leadership strategy underpins all employee operations and is designed to bolster the wellbeing of all staff. The philosophy centres on staff-centric approaches, ensuring they have bespoke support, respect and dignity, allowing them to have a happy and fulfilling work/life balance. With Bob Chapman: CEO of Barry-Wehmiller at the helm, this strategy helps company leaders across the board engage with their teams with empathy and compassion, leading to higher work morale and therefore, optimising customer service levels.”

“With excellence running through all divisions, from technical support, to sales and manufacturing, BW Flexible Systems has become synonymous with innovation, “Innovation indeed ranks highly among our top priorities, so we remain relevant and a continued pioneer of solutions for all markets. Whether through in-line printing options, increasing options for packaging material, or providing more and better training to operators, we will continue to build our product offering and support services.”

“Many of our products are the result of specific customer requests and we will continue this customer-centric approach to provide our customers what they want and need, instead of adapting the customer’s needs to what we offer,” added James.

BW Flexible Systems for example, offers solutions for free and semi-free flowing products: incorporating a wide range of bag types and sizes. With a rich history of expertise, the design-team has come up with machines that work with a variety of applications, across free-flowing and semi free-flowing products.

BW Flexible Systems for example, offers solutions for free and semi-free flowing products: incorporating a wide range of bag types and sizes. With a rich history of expertise, the design-team has come up with machines that work with a variety of applications, across free-flowing and semi free-flowing products.

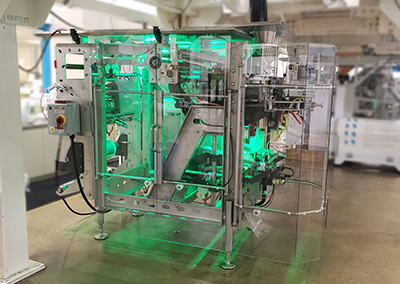

The Hayssen ISB (Intelligent Sanitary Bagger) is an ingenious vertical form fill seal (VFFS) bagger, perfectly designed for the fresh, frozen, IQF foods, cheese/dairy, meat, poultry and seafood sectors and is a machine of choice for many companies. The equipment includes state-of-the-art features such as: open channel framing and design, convenient modular design for varying customisation, cutting-edge wire routing negates the need for zip-tired wire bundles and many more benefits, such as premiere polymer doors. This bagger provides optimised, compliant, hygienic packaging solutions, with the TruFORM forming set removable component giving an orderly, consistent bag shape during the packaging process.

Operators can easily clean the machine, thanks to its open channel frame, with sloped surface. For industries like food production, where flawless sanitation is demanded at all times, the Hayssen ISB Bagger is precision-designed to tolerate high-pressure washdowns and the IP66 and NEMA 4X enclosure ratings and polymer doors further protect the machine from water and other impurities. Furthermore, the film-threading feature ensures streamlined easy film loading, for next generational production line functionality.

With visibility throughout, centre-driven powered film unwind, convenient pass-through film threading, swing-out electrical box with low and high voltage access doors, and FTA changeover safety, this bagger is market-leading for sanitary packaging environments.

With visibility throughout, centre-driven powered film unwind, convenient pass-through film threading, swing-out electrical box with low and high voltage access doors, and FTA changeover safety, this bagger is market-leading for sanitary packaging environments.

As we approach the UK Government’s 2050 net-zero targets and with an increased focus on the circular economy, BW Flexible Systems has prioritised its sustainability best practice, with eco-friendly packaging solutions. Many companies are now looking to substantially reduce waste by investing in more sustainable, recyclable, paper-based and compostable materials.

The expert team at BW Flexible Systems can help with retrofitting existing equipment and even supply parts that run with lightweight and biodegradable materials, optimising sustainability best practice.

BW Flexible Systems truly offer world-class manufactured flexible packaging solutions, from: bag filling and palletising, vertical form-fill-seal, and horizontal flow wrapping, across diverse industrial applications.

Here at Industry Update, we like to celebrate innovation and this company offers truly pioneering global packaging systems. With over 100 years of expertise, innovative product range and a unique approach to staff morale, through the Truly Human Leadership scheme, this company clearly looks after its people, customers and enhanced product range. BW Flexible Systems is a worthy recipient as our Packaging Systems Company of the Year and we asked James how it felt to be selected, “We are both honoured and humbled to be selected for this award. Though we are confident in our skills and our product portfolio, we also know there are still many new things to be discovered and perfected upon, and this award is a reflection of the potential that BW Flexible Systems brings to the table.”

Here at Industry Update, we like to celebrate innovation and this company offers truly pioneering global packaging systems. With over 100 years of expertise, innovative product range and a unique approach to staff morale, through the Truly Human Leadership scheme, this company clearly looks after its people, customers and enhanced product range. BW Flexible Systems is a worthy recipient as our Packaging Systems Company of the Year and we asked James how it felt to be selected, “We are both honoured and humbled to be selected for this award. Though we are confident in our skills and our product portfolio, we also know there are still many new things to be discovered and perfected upon, and this award is a reflection of the potential that BW Flexible Systems brings to the table.”

“It is important to us to have honest, transparent, and holistic conversations about what we offer but also where we as an industry should invest more time and resources, ranging from sustainability, to optimised leadership, as well as offering our customers innovative solutions that facilitate packaging and supplying.”

“We are honoured to be selected for this award and look forward to hearing from our current and future customers about their needs, inventing new solutions, and defining how and where the future of the industry can grow.”

BW Flexible Systems will be at the following high-profile trade exhibitions:

Pack Expo East:

18th-20th March 2024, Philadelphia, USA (Stand 616) – showcasing Hayssen brand

Cheese Expo:

16th-18th April 2024, Milwaukee, USA.

(Stand 1401/1403) – showcasing Hayssen brand

FachPack:

24th-26th September 2024, Nuremberg Exposition Centre, Germany.

For more information about BW Flexible Systems, please see company website below:

T +44 (0)115 967 8787 (UK: Nottingham)

https://www.bwflexiblesystems.com