In the high-stakes environments of modern research and manufacturing laboratories, the pursuit of precision is relentless. Yet, a fundamental instrument – the microscope – often introduces a significant variable: human fatigue. Analysts performing intricate inspection tasks for prolonged periods, often within the sterile confines of a laminar flow cabinet, are all too familiar with the neck, back, and eye strain associated with traditional binocular microscopes. This physical toll is not merely a matter of comfort; it is a direct threat to concentration, productivity, and data integrity, increasing the risk of costly errors and diminished throughput.

The challenge, then, is to decouple high-performance microscopy from the physical strain it imposes on the operator. What if the very design of the microscope could eliminate this ergonomic bottleneck, fostering sustained focus and elevating the quality of output?

The challenge, then, is to decouple high-performance microscopy from the physical strain it imposes on the operator. What if the very design of the microscope could eliminate this ergonomic bottleneck, fostering sustained focus and elevating the quality of output?

A new vision: The shift to eyepiece-less technology

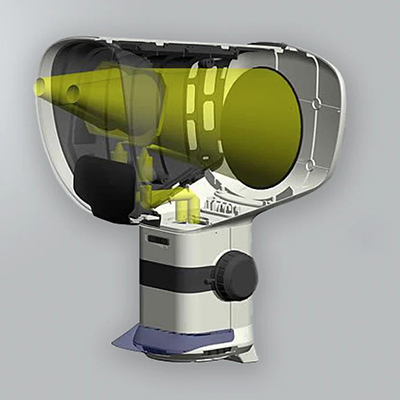

A revolutionary step forward in optical instrumentation is addressing this challenge head-on. The Lynx EVO, a Queen’s Award-winning stereo microscope, exemplifies this new approach with its patented eyepiece-less optical technology. By eliminating the restrictive eyepieces of conventional microscopes, it projects a high-resolution, three-dimensional image into the user’s natural field of view.

This fundamental design change allows operators to adopt a comfortable, upright posture, liberating them from the hunch that has defined microscope work for over a century. The immediate effect is a dramatic reduction in musculoskeletal stress and visual fatigue. For the laboratory, this translates into operators who can remain focused for longer, leading to a measurable decrease in inspection errors and a consistent level of productivity throughout the working day.

Optimising for critical environments

The benefits of this ergonomic design are particularly pronounced in specialised applications. The superb optical clarity and high-contrast 3D imaging empower confident decision-making across diverse fields, from electronics inspection to biological sample analysis.

Furthermore, the Lynx EVO’s open architecture and significant working distance make it exceptionally well-suited for sterile applications inside laminar flow cabinets or clean rooms. Unlike traditional microscopes that can obstruct airflow and crowd the workspace, its design maintains the integrity of the sterile environment. This gives operators unrestricted access to manipulate samples with ease, a critical advantage in medical device manufacturing, cell culture, and other contamination-sensitive processes.

Furthermore, the Lynx EVO’s open architecture and significant working distance make it exceptionally well-suited for sterile applications inside laminar flow cabinets or clean rooms. Unlike traditional microscopes that can obstruct airflow and crowd the workspace, its design maintains the integrity of the sterile environment. This gives operators unrestricted access to manipulate samples with ease, a critical advantage in medical device manufacturing, cell culture, and other contamination-sensitive processes.

Expanding capabilities for complex inspection

Advanced inspection often requires viewing subjects from multiple angles. To address this, the Lynx EVO’s utility can be expanded with innovative accessories like the Oblique and Direct Viewer. This attachment enables the operator to view a subject from an angle and provides a full rotating view around the feature of interest without needing to touch or reposition the sample itself. This capability is invaluable for the detailed, non-destructive inspection of complex components such as solder joints, biomedical implants, and archaeological artefacts, revealing critical details that might otherwise be missed.

Ultimately, investing in advanced ergonomic instrumentation is a strategic decision that extends beyond operator wellbeing. By directly addressing the physical factors that limit human performance, laboratories can achieve a higher standard of precision, improve workflow efficiency, and empower their teams to deliver more reliable, breakthrough results.

To learn more about the Lynx EVO eyepiece-less stereo microscope and its applications, you can explore the resources below.

To learn more about the Lynx EVO eyepiece-less stereo microscope and its applications, you can explore the resources below.

T 01483 248300

enquiries@visioneng.co.uk

https://www.visioneng.com