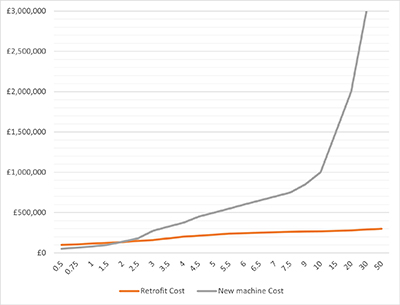

When considering updating machine-tools there are a number of factors that drive the decision whether to retrofit, or replace a machine-tool, and it’s not always down to direct cost comparison. Many retrofitters won’t even quote for machines with less than 1.5m2 capacity. Not just because they can’t compete with the cost of a new machine, but because it makes them look overpriced, so could affect the possibility of quoting for larger machines or other services. Using a sliding scale of approximate cost comparison according to machine capacity in m2, it’s easy to see how increasing machine capacity transfers the balance towards retrofitting.

The main differential driver is economy of scale, which has a number of factors.

The main differential driver is economy of scale, which has a number of factors.

- Hardware cost: Retrofits are generally offered by small companies such as us, that don’t have the volume, and therefore the purchasing power to demand large discounts from the systems suppliers. They can’t even buy the hardware for less than many machine-tool manufacturers are selling entire small machines. Whereas, machine-tool manufacturers have the production volumes to do so, and the cost difference is substantial. Economy of scale.

- Machine capacity: As a measure of the size of the machine. The larger the machine, the lower the production volumes and higher the production costs. Then it starts to shift in favour of retrofitting. Large machines are considerably cheaper to retrofit than to replace. Especially when you factor in the cost of special foundations etc.

- Mechanical condition: The condition of the machine dictates whether mechanical refurbishment of some elements such as linear guideways, ballscrews, pumps, guarding etc. need to be addressed as well. A new control system won’t improve worn mechanics, it’s more likely to reveal the problems. However, a retrofit is the ideal time to address these issues while the machine is out of production anyway.

- Downtime: Can production accept the downtime to install the new system?

Is it more cost-effective to buy a new machine and just swap it over?

Again, the larger the machine, the greater the time to install and commission.

Our Retrofit systems are built off-site, pre-commissioned and tested prior to installation. Minimising the on-site install time, again it’s relative to the size and complexity of the machine. - Diversity: This means non-standard, so low production volume, higher cost and longer lead-times for replacement machines. It makes more sense to retrofit the current asset.

- Reliability: Often in large machine shops you find an old workhorse of a machine stuck in a corner somewhere, running on an ancient CNC system kept running by any means. The cabinet looks like it houses bats. It doesn’t get powered because it might not power up again.

Why do they still exist? Because mechanically they are solid, reliable and reasonably accurate. They cost little to keep going – if the parts are available to repair them – and the downtime doesn’t hurt so much because they are usually a backup machine when production gets tight, or other machines are down. These machines usually fall into the crossover size of around 2m2 capacity, so the cost of retrofitting can almost be justified, but a new machine would also be a viable option.

So why retrofit one of these machines? The answer is precisely the reason it’s still in the workshop. It’s mechanically robust and in reasonable condition. Newer machines are built to a budget and rarely as robust as the old workhorses.

If you are running these machines to supplement production you rely on them because of problems in other areas, so you don’t want it down for weeks waiting for parts that are increasingly difficult to source. -

Figure 1 – Cost per m2 capacity Compliance: Retrofitting can, and often does, force compliance to current safety standards, but this is an opportunity to improve safety on the shop floor with new guarding systems etc. which vastly reduces the risk of lost time accidents and the inevitable follow up litigation.

Many factories hide behind the ‘Old control system’ as an excuse not to comply with current standards, they think it’s not a requirement for old systems, but that’s not strictly true. The old control isn’t required to have SIL3/4 or PLd/e safety systems, but it still has to be safe. A PUWER assessment will reveal the non-compliances, especially around guarding, operator ergonomics and safety. There really is no excuse. - Program compatibility: Programs require re-writing for the new system.

Often, yes, but most old machines are programmed manually, by the operator, because it’s no longer compatible with the factory data connection. A new control system will be compatible with the up-to-date programming strategies of the newer machines in the factory, so will integrate readily.

If you have machine-tools in need of an upgrade, give us a call. We can help you.

T 07787 553251

info@effectivecncsolutions.co.uk

www.effectivecncsolutions.co.uk