Industry Update is proud to feature RMIG as our Editor’s Perforating Company.

As the largest perforating company in the world, RMIG has over a century’s experience in the perforation industry. This impressive size and experience means RMIG has a local presence in a range of markets, providing accessible contacts for customers no matter what their query. From RMIG’s multiple manufacturing sites, your contact person can make use of an exceptional level of experience in manufacturing and application knowledge.

Given that RMIG’s high quality perforated products are supplied to demanding industries, providing quality assurance is of vital importance to the company. Its drive for total quality throughout the business is fundamental to providing continuous satisfaction for its customers, and RMIG ensures it offers effective operational systems implemented in a consistent manner to reflect the needs of both the customer and the business.

With the vision to be ‘The Best Choice’ for its customers, shareholders and employees, RMIG is dedicated to being an innovative and reliable solution provider in the perforation industry, as well as being recognised as a benchmark for customer service and optimised logistics. This commitment to quality in both manufacture and service has helped RMIG’s continued growth for over 100 years, with more successes most definitely on the horizon for the company.

RMIG’s perforated sheets can be used effectively within a number of areas, and RMIG has six dedicated market sectors including Industrial Processing, Food Processing, and Buildings and Interiors.

Industrial Processing

Industrial Processing includes a vast range of potential applications for perforated products. RMIG has extensive experience in the chemical, pharmaceutical, paper, and offshore industries, to name a few. From small, high precision perforation in thin materials to large holes in thick sheets used in the mining industry, RMIG has the knowledge, versatility, and tooling to deliver products according to customers’ requirements.

One particular area of Industrial Processing is dealing with waste water. The water industry presents a number of unique challenges in the use of perforated products. A key consideration here is the aggressive nature of the water towards the materials being used. RMIG has vast experience in servicing the waste water industry, and produces high flow, burr-free perforated waste water screens, offering accurate screen tolerances and effective separation.

Another area of Industrial Processing is medical and pharmaceutical, where RMIG’s perforated materials are able to give firm tolerances during their manufacture, and are well suited for use in sterile environments. RMIG’s perforated products also have numerous uses in the petrochemical sector, from industry specific applications such as filtration, to oil and gas exploration, as well as more general applications such as walkways in processing plants.

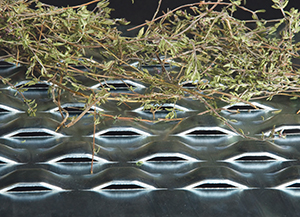

Additionally, RMIG works with biomass drying applications. The demand for alternative sources of sustainable and renewable energy is always growing. RMIG’s Bridge Slot sheets are the most effective way of drying woodchip to an optimum moisture content, ensuring boilers operate efficiently to benefit farming and agriculture.

The RMIG Bridge Slot sheets play an essential role when it comes to the design and manufacture of biomass drying floors. The combination of sheet thickness and opening size allows RMIG’s sheets to be used either as a suspended floor in wood chip drying containers and trailers, or as drive-on drying floors in outdoor buildings. The bridge slot opening size determines the products that can be dried, which range from fine oilseed rape through to larger grains and cereals, as well as logs and wood chip drying.

Food Processing

RMIG’s Food Processing market sector meets the high levels of hygiene demanded by the food processing industry. Perforated screens are also strong with important thermal capabilities, making them useful for a wide range of food processing applications. RMIG’s tailor made perforated solutions are ideal for cleaning, heating and steaming in food production environments. Whether it’s baking trays, cereal cleaning or ingredient conveyors, all of RMIG’s perforated materials can be customised for each application.

Buildings and Interiors

One of RMIG’s most exciting market sectors is Building and Interiors, where new perforated materials can stimulate intriguing urban designs across lighting, facades, balustrades, sun screens and ceilings. RMIG’s perforated products can create highly innovative lighting designs, and with the company’s experience in combining design and functionality, it can easily manufacture solutions to meet your needs.

RMIG can also help create visually stunning facades. Its innovative technologies and materials can capture the passion for creative urban design and realise even the most ambitious architectural projects. Whether it’s a perforated, embossed or indented facade or a combination of these, RMIG can guide customers in the benefits and practicality of producing the design. As well as perforating, RMIG can also cut, bend, shape and take responsibility for the finish, including powder coating, galvanising and more.

So, no matter what your requirement, RMIG has the knowledge, experience, and manufacturing expertise to ensure you get the perforating solution that you need. To find out more information on RMIG and everything it offers, head to the website or get in touch using the details below.

T +44 (0)1925 839610

info.uk@rmig.com

www.rmig.com/en