Schmersal to showcase application-specific safety concepts at SPS

Whether safety solutions for new machinery and systems or a safety retrofit on older machinery, safety concepts need to be both flexible and efficient whilst helping to achieve greater productivity. At SPS, in Nuremberg, the Schmersal Group will be showcasing a range of new products as well as intelligent package solutions for machinery safety that are designed to be adaptable to individual applications and to meet new standard requirements.

New evaluation logics – For example for wind turbines

Schmersal will be introducing new versions of its multifunctional SRB-E series of safety relay modules at SPS. The SRB-E series, as well as the PROTECT SELECT safety compact control unit, combines maximum safety with straightforward usability and a high level of flexibility. This makes them suitable for use on the lift systems in wind turbines, which following changes to standard EN 81-44, are now subject to new safety requirements. An important new demand is that the safety-related parts of the control unit must now satisfy PL d in accordance with EN ISO 13849-1. Both the SRB-E product series and the PROTECT SELECT are capable of achieving this safety level. Combined with position switches and other safety components from Schmersal, these products can accomplish functions such as lift door monitoring in wind turbines, overload protection, direction monitoring and operate as limit stops.

Safety Fieldbox reduces installation effort

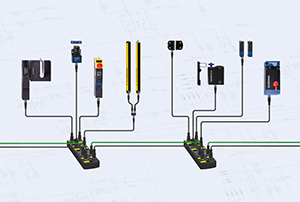

Schmersal will also be showcasing an overhauled version of its Safety Fieldbox at SPS for the first time. The Safety Fieldbox allows different safety switchgear – from solenoid interlocks to safety sensors and safety light barriers – to be decentrally connected and freely linked in the field. Unique to the device is the ability to connect up to four control panels with EMERGENCY STOP buttons and as many as three non-failsafe command and signalling devices. This simplifies the wiring effort required of users, minimises installation effort and enables wide-ranging diagnostics functions.

A perfect combination for retrofits

Schmersal will also be using SPS as an opportunity to present innovative interlocks, such as the AZM161 and AZM300, as well as control panels, such as the BDF200, and new versions of evaluation logics, such as the SRB-E-402FWS safety relay module. Combining these components gives users the perfect out-of-the-box solution for older machinery, allowing them guard against hazardous run-on movements on rotary machinery. The SRB-E-402FWS safety relay module combines the functions of failsafe two-channel time monitoring with failsafe two-channel guard door monitoring in a single device. Guard door monitoring is handled by a solenoid interlock, such as the AZM161 electromechanical solenoid interlock or the AZM300 electronic interlock, the latter being fitted with a security-enhanced RFID sensor. A type BDF200 operating unit is the control unit and third component in the retrofit package solutions. Thanks to its compact size, the assembly can be mounted directly to the guard door.

Visit Schmersal at SPS – Smart Production Solutions – Stand 460, Hall 9 between 8th-10th November 2022.

Steve Watkins,

swatkins@schmersal.com

www.schmersal.co.uk