Kingston Engineering is one of the UK’s leading manufacturers of bespoke power screws. Based in Hull, the company offers a vast selection of materials and specifications designed to suit their clients’ requirements.

With a history dating back to 1919, Kingston Engineering has specialised in manufacturing Right Hand/Left Hand, single/multi-start, cut thread Power Transmission Screws and Nuts for over 60 years. Adaptable for mechanical power transmission, their products conform to the standards of British, European and American requirements. All of Kingston’s products meet ISO 9001-2015 accreditation and are examined thoroughly during the manufacturing process.

With a history dating back to 1919, Kingston Engineering has specialised in manufacturing Right Hand/Left Hand, single/multi-start, cut thread Power Transmission Screws and Nuts for over 60 years. Adaptable for mechanical power transmission, their products conform to the standards of British, European and American requirements. All of Kingston’s products meet ISO 9001-2015 accreditation and are examined thoroughly during the manufacturing process.

Kingston Engineering’s screws can be used in a range of applications across multiple industries, including aerospace, oil and gas, nuclear energy, the chemical and medical fields. The company works closely with both suppliers and end users to provide the best purpose-built screws possible, with customers across the UK and the US.

The company started trading as Hull Motor Transport and Engineering Co, manufacturing pistons and providing cylinder grinding. Robert Markham and Thomas Simpkins, the company’s original directors, focused on offering a bespoke service, which is something the company still upholds today. With only 10 employees, expansion was nevertheless on the horizon, enabling the company to provide general engineering services and build a renowned reputation for repairing both saw milling machinery and printing machinery.

The company became Kingston Engineering Co. Ltd in 1924 and started developing manufacturing screws in 1930. Growth during decades marked by World War One and World War Two was challenging, however 1930-1945 saw expansion for Kingston Engineering, with World War Two bringing a need for manufacturing components for aircraft undercarriages.

The company became Kingston Engineering Co. Ltd in 1924 and started developing manufacturing screws in 1930. Growth during decades marked by World War One and World War Two was challenging, however 1930-1945 saw expansion for Kingston Engineering, with World War Two bringing a need for manufacturing components for aircraft undercarriages.

After World War Two, the company operated from a larger site in Pennington Street and began to specialise in screw manufacturing. Kingston Engineering began to install modern machinery, giving them the perfect platform to grow and open new markets in Australia and South Africa.

In the sixties the company moved from motor sales to industrial sales, with further investments in its factory, export market, modern machinery, product range and ‘Off the Shelf’ service. Kingston Engineering now had extremely well-equipped workshops, enabling them to accommodate facilities for milling, shaping, welding, grinding and turning.

Kingston Engineering further expanded their factory premises and their product range, leading to a vast range of screws, sprockets, chains, pumps and bearings. They also expanded their sprayed coating services and began exporting across Europe. The eighties saw digital technology further increase Kingston Engineering’s already established skillset.

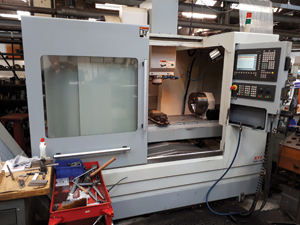

Now, Engineering provides a quick, efficient service with help from their 40+ workforce. Recently, they invested in a new Mituoyo Euro M544 Measuring Machine, a significant tool for their inspection department. The machine allows the measurement of an object’s physical geometrical characteristics. The machine creates printed inspection reports and is controlled by an operator, with measurements designed by a probe attached to the machine’s third moving axis.

It is clear to see that over the years, the company has significantly invested in their machinery for continued success. The current directors have more than 100 years of experience between them and are continuously engaging in plans to help the company become global leaders in screw manufacturing.

Contact

T 01482 325676

www.kingston-engineering.co.uk